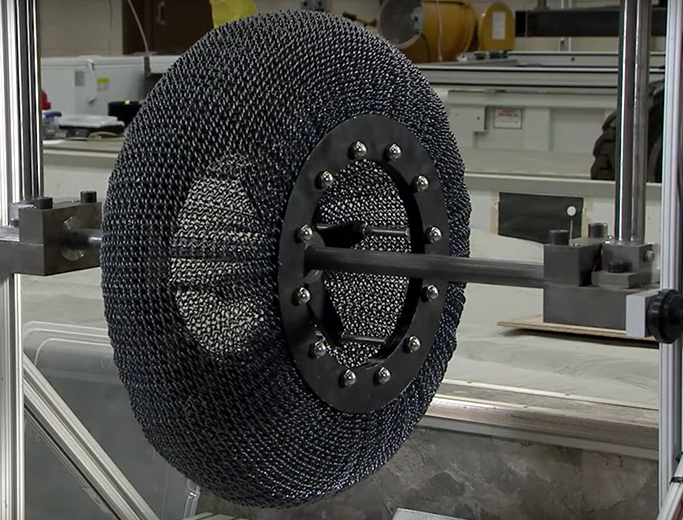

Sending missions to other celestial bodies is tough, with a lot of aspects to be considered. Even the most basic, like tires, have to be well-thought out, due to extreme terrain. This is where NASA’s (National Aeronautics and Space Administration) new Superelastic Tires come in.

Unlike the elastic materials used for normal cars, these tires are built using a Shape Memory Alloy, made mainly of Nickel-Titanium (NiTi). It can withstand up to 10% of strain: which is exponentially more than other common elastic materials, which irreversibly deform after just 0.3–0.5% of strain. Superelastic Tires are also puncture-proof and air-independent– this results in efficient fuel use, as you never have to worry about the vehicle running ‘under-inflated’!

Design wise, the alloy can be used in the radial elements instead of the normal springs; this increases their load-carrying capacity. Its stiffness can be manipulated to ensure minimal energy transfer to the vehicle. But the cherry on the cake? It’s that even with all these benefits, it’s lightweight — there’s no need for an inner frame.

What’s more, is that this wheel has potential back on Earth too. It could be applied in military vehicles and heavy-duty trucks, allowing them to travel with ease at much higher speeds. In conclusion, NASA’s Superelastic Tires could be the innovation that revolutionises travel, and reinvent transportation.

- Medha Gopalakrishnan

Sources:

- https://www.zmescience.com/science/news-science/nasa-wheel-no-punctures/

- https://technology.nasa.gov/patent/LEW-TOPS-99

*Disclaimer: This article has also been posted to our Medium. NernstNaK is the rightful owner of this work on both our website and Medium, and thus stresses that there has been no plagiarism or copying on either account.*